OUR FABRIC

FASO DANFANI

DIFFERENT PHASES

In dioula, native to Burkina Faso, Côte d'Ivoire and Mali, Faso Dan Fani means « woven fabric at home ». Cotton grown in the country is processed through many stages ranging from ginning, spinning and dyeing to weaving and sewing. These cotton fibres are either spun by hand or spun industrially in a Burkinabe factory, while weaving and dyeing cotton yarns remain strictly artisanal. Before producing the first metre of fabric, almost 15 days of yarn preparation and weaving are required. On average, weavers will produce about 2 meters a day.

Ginning

CARDAGE

FILING

TESTING

SUPPLY

TISSAGE

CUTTING

QUALITY CONTROL

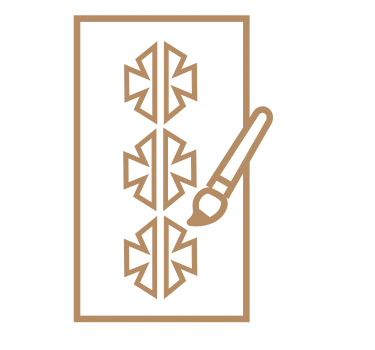

KOKO DUNDA / CRAVATE – MATRICES

Kôkô Dunda is from the town of Bobo Dioulasso in Burkina Faso. The name literally translates as "the entrance to the Kokô", the name of the Bobo Dioulasso district where the dyers traditionally work.

fold and tie (different methods)

+

Dyeing

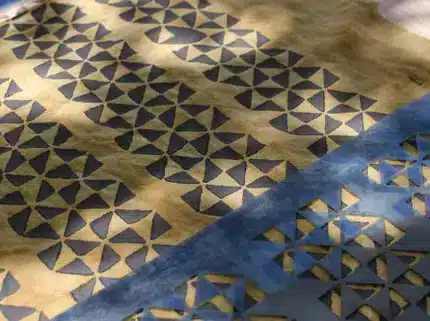

BOGOLAN / HEADING

Bogolan/Mud Dye is a Malian textile dyed according to an ancestral technique familiar to Burkina Faso, Guinea, Côte d'Ivoire and Senegal. The word bogolan, of the Bambara language, derives from the words bogo, meaning « Earth », and lan, meaning « of the ». The basic dyes are generated by soaking the fabric in a decoction of African birch leaves (n After the basic dyes, the drawings are made in sludge fermented with a delicate brush.

soak and dry the fabric

+

draw drawing with fermented mud

+

Dipping and drying to get a darker tone

INDIGO

Colouring material blue violet extracted from the leaves and stems of indigotier, the indigo derives its name from the resulting dark blue coloration. In Africa, the two most used indigo plants are Indigofera Arrecta and Lonchocarpus Cyanescens. The first grows in dry areas and gives a blue called « savannah blue » and the second, more widespread in West Africa, produces an indigo plant colour called « blue forest ». The leaves harvested from these plants are used to prepare the dye, which are used fresh or dried and are compacted into balls or paste, which are then diluted.

+

Dipping and drying to get a darker tone

BATIK

Batik is a fabric printed by coating parts of wax, using wooden pads to carefully place wax on the fabric. Once the wax is completely dry, the fabric passes first into a dye bath, followed by a hot bath where the wax melts and the final result is visible.

+

dyeing and dewaxing